Hard Apple Cider

As a rite of passage, every new brewer has to make a hard cider. Did you know it’s only called “hard cider” in the US? Everywhere else in the world, the fermented apple juice beverage is known as “cider.” Interesting Americanism isn’t it?

Section Index

Ingredients

- 365 Organic Apple Juice (64oz)

- Martinelli’s Organic Apple Juice (64oz)

- Lalvin D47 yeast

- 1 stick of cinnamon

Preparation

Most of my materials were already santizied since I mixed the Cider brew just after I finished mixing the Must for Blood Orange Mead. I rinsed the turkey baster, hydrometer, and graduated cylinder and set it aside. I thoroughly cleaned and sanitized a carboy, bung, a funnel, and 3-piece airlock.

I bought two different kinds of apple juice because I was curious if the $10 bottle was the same as the $3.50 bottle. After opening them I poured off a small amount and tasted them. The Martinelli’s apple juice tasted much more tart and fresh than the 365 brand. But, honestly… there wasn’t enough of a difference, in my opinion, to justify spending $20/gallon for this higher end apple juice. The next cider I make will be 1 gallon of 365 brand apple juice.

Mixing cider is super straight forward. I shook out the drops of rinse water from the carboy and then put the funnel on the top. Then, I dumped in both jugs of apple juice. The fluid level was right up the next of the carboy and I was concerned this was too much fluid. So I poured out enough to put the fluid level down around where the lettering on the glass is (I was happy I did this the next day). I added a handful of finely chopped raisins, 1 whole cinnamon stick, and 4oz of tea brewed from a single black tea bag. The black tea has been suggested by City Steading Brews so I wanted to try it out.

After all the ingredients were added, I put a clean and sanitized screw-on cap on the carboy and shook the contents vigorously. There wasn’t much in the carboy to actually mix, but I wanted to ensure there was plenty of oxygen in the cider for the yeastie boys to get their colony started. I removed the cap and noticed the strong and rather delicious apple juice smell coming from the carboy. I used the clean turkey baster to draw enough cider to float the hydrometer in the graduated cylinder and noted the beginning Specific Gravity (SG) was 1.045. This allows a theoretical maximum of about 5-6% ABV, if brewed to dryness.

Finally, I added a whole packet of Lalvin D47 yeast to the cider. I did not stir or mix in the yeast, but I did note that in a few minutes, it had all sank into the cider with no assistance. I placed the 3-piece airlock into the bung, added the appropriate amount of clean water to the airlock, and put the bung into the carboy.

The Cider Puked

05/08/2023 – I woke up and checked in on the brews. I’m glad I did this morning. My intuition about the cider being too high in the neck of the carboy was right. Overnight, the yeastie boys got to work in a furious way causing so many bubbles the foam eventually climbed into the airlock. I took the bung out of the carboy, removed the 3-piece, and dumped out the contents. While the bung was out, I swirled the cider several times to attempt to degas it a little bit. But the yeast is clearly super active to the point that I don’t think I was doing much good. Since there is a cinnamon stick in the carboy, the CO2 does have something to nucleate on and come out of solution, so it should be ok. Since I was using clean water in the airlock, I refilled the airlock and put everything back together on the carboy. Look at this video of the amount of CO2 being generated! It’s crazy!

Super yeast

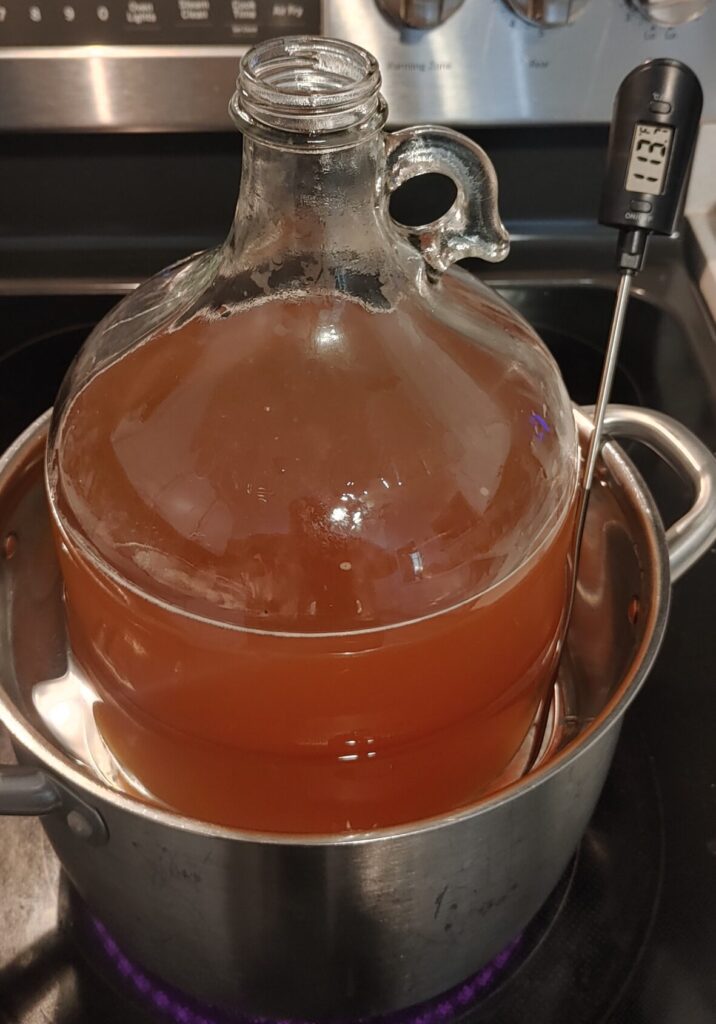

As I suspected, the yeast were extremely happy. They tore through the 1.045 SG to dryness in 48 hours. Not even kidding a little bit. I noticed the airlock activity had stopped so I drew up a sample with the turkey baster and put it into the graduated cylinder with hydrometer on 5/9 Tuesday and got a reading of 1.000 SG. Since all equipment was sanitized, I poured the sample back into the fermentation vessel. I waited another three days and noticed no additional airlock activity. I pulled another sample on 5/12 Friday and found it to be still 1.000 SG. I decided to go ahead and pasteurized the cider (to kill the yeast) and back-sweeten. To ensure the yeast are dead, head until 140F and hold for at least 10 minutes.

I used brown sugar to back-sweeten. When it was the sweetness I liked, I took a final sample and measured 1.010 SG.

Bottling

I just got a new bottling stem and a dozen 750ml glass wine bottles for my projects. I washed and sanitized these new items and bottled off the cider for aging. The end result was a cinnamon apply, buttery even, hard apple cider. I bet it ages super well and tastes even better soon! Thanks for following along on this one.