Texas Blueberry Mead

My first batch. Looking forward to the learning experience!

I’m using an S-type airlock with a 1 US gallon glass carboy. Sanitized with Five Star IO Star Iodine based sanitizer (requires rinsing).

Section Index

- Preparation

- Mixing the Must

- The Blueberry Modification 04/29/2023

- Gravity Check 05/03/2023

- Pasteurization

- Backsweetening

- All gone 05/08/2023

- Mistakes

- Comment Section

Ingredients

- Desert Creek Texas Honey (2lbs)

- Red Star Cote de blancs yeast (whole packet)

- LD Carlson yeast nutrients

- Frozen Blueberries (organic)

Preparation

I prepared a full gallon of sanitizer in cool water in a metal bowl. I sanitized my carboy, metal cap, rubber cork, s-type airlock, funnel, medium size mason jar, graduated cylinder, and hydrometer.

In a separate cooking pot, I boiled about half a gallon of tap water. I kept this water at a rolling boil for 15 minutes to burn off the chlorine and kill any badies swimming around in city water. Once done, I set aside to allow to cool. Meanwhile, I filled the mason jar with cold, filtered water. The filter we have removes microbes as well as chlorine, so no boiling this was necessary. This was set aside adjacent to the pot of boiled tap water.

Mixing the Must

I placed the carboy on the counter and put the funnel on top. I wasn’t very sure about if the glass of the carboy was tempered or not so I started with very small additions of the still hot boiled water and swished it around to warm the glass slowly. Once I was happy the carboy wouldn’t shatter, I put about 1 inch of water in the bottom. My IR thermometer said the water was about 140F. Next, I opened the honey and poured as much as the funnel would hold. After a few seconds, I added more hot water to the funnel which melted the honey and helped it flow through into the carboy. I repeated this process, some honey, some hot water, until all the honey was added. I splashed some hot water into the honey bottle, put the honey bottle cap back on, and shook vigorously to get all the honey; then poured that into the carboy as well. I added 1 teaspoon of the yeast nutrient as well. Then, I used the metal sealing cap to close the carboy and shook the mixture until I was happy it was thoroughly mixed.

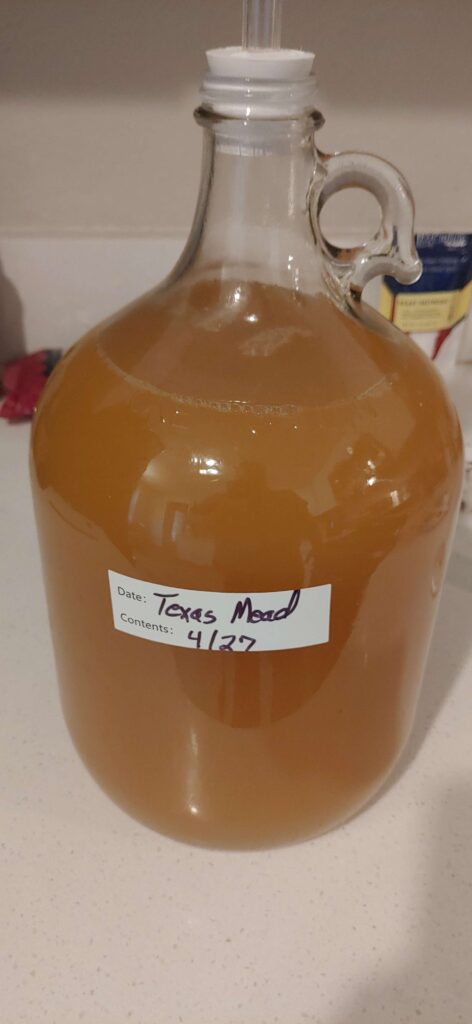

Once that was done, we have our Must…. but it’s still very hot. Temperature reading said about 120F. This is likely too hot for our little yeastie friends and this is where the cold filtered water comes in. I added enough cold water to get the Must down to 80F. Once done, I pitched the yeast.Mistake #1 I added the full packet because you really can’t have too much yeast and I wanted to get the Must as dry as possible at the end of fermentation. Recapped with the metal lid and shook the carboy briefly to mix in the yeast well. This was not a vigorous shake, just enough to incorporate the yeast. I removed the metal cap and carefully poured some off into a glass graduated cylinder. Using my hydrometer, I determined a starting specific gravity (SG) of 1.070.Mistake #2 Since the cylinder was sanitized prior to use, I added the sample back to the carboy. With a paper towel, I dried the inside of the neck where the rubber cork would touch. I also verified the rubber cork itself was dry. Then I put the s-type airlock into the rubber cork and corked the carboy.

The Blueberry Modification 04/29/2023

After learning my target ABV of 15% would not be theoretically possible with a starting SG of 1.070 (mistake #2), I decided to sweeten the Must with a shot of blueberry syrup. I already planned to back-sweeten the finished mead with blueberry, but realizing I’d be short on my ABV goal, I decided to try adding a shot of blueberry syrup to the Must. I took the frozen blueberries, thawed them, and then added them to a small sauce pan with a splash of filtered water and about two tablespoons of sugar. I heated this mixture until it was about 160F, but I didn’t want to boil the mixture and lose volatile flavor compounds. I held the mix around 160F, stirring frequently and crushing berries, for about 10 minutes, then poured out onto a clean plate to rapidly cool. I did the ‘swirl’ maneuver several times with the carboy to degas the Must since I know adding whole fruit would cause a lot of bubbling since CO2 would have something to latch on to and come out of solution.

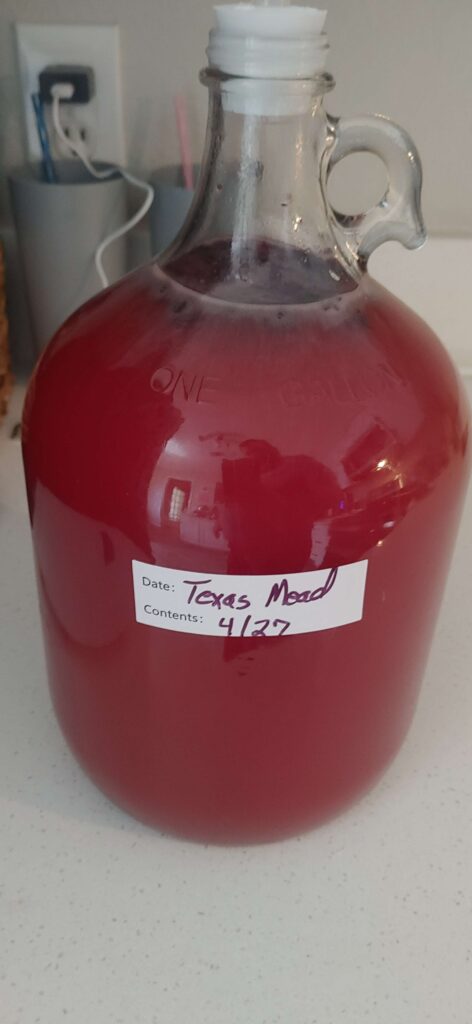

I sanitized my funnel, removed the airlock and rubber cork from the carboy, then put the funnel on the carboy. Once the blueberry syrup mixture goo was around 80F (safe for yeast) I slowly added the syrup and several chunks of squished fruit to the carboy. Once done, I replaced the airlock and rubber cork and swirled the mixture around some more to get it well mixed in.

The bubbling in the airlock was much more intense as the CO2 could come out of solution readily, but it never puked into the airlock or bubbled over.

Gravity Check 05/03/2023

On 05/02, I noted airlock activity had slowed tremendously. I’ve recently discovered City Steading Brews and thoroughly enjoy the outstanding pair of YouTube brewers. They have a lot of great information and share their real-life lessons learned. The pair is also really entertaining and fun to watch. One of the things I’ve learned from them is to be in the habit of checking specific gravity when you think a brew is done, then letting it sit another week to verify the gravity hasn’t changed. I intend to adopt this policy in my own brewing so today, I’m doing the first new SG check. To start, I fetched the fermentation vessel from the Magic Altar of Alcohol Genesis and sanitized a turkey baster, graduated cylinder, and hydrometer. Using the turkey baster, I drew up enough Must to float the hydrometer and found the SG to be 0.998.

My first Must had fermented to dryness! Very cool. I poured some of the SG sample into a cup for tasting. It tasted dry with notes of honey, generic fruity flavor, and of course, ethanol. I then prepped for racking and pasteurization.

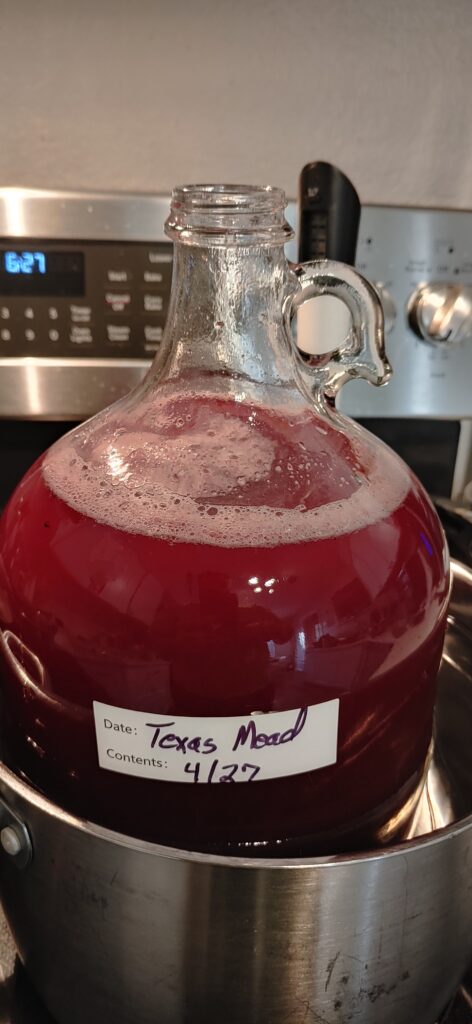

Pasteurizing

There are many methods for killing off the yeasties when you’re done with them. Again, opting to follow my family’s desire to keep things as natural as possible and avoid chemical interventions where able, I decided to pasteurize my Mead. I put the carboy with the freshly racked Mead into a large pot. I also put a canning rack in the pot so the glass carboy would not be in direct contact with the bottom of the pot. This could cause the glass to shatter during heating. I added 80F water to the pot until there was no more room. I turned on the stove with very low, very gentle heat. My stove’s controls are “Lo” (1) to “Hi” (9) and I heated the Mead slowly at about “2” or “3” on the stove control. I held the Mead at 140F for 10 minutes to kill off the yeasties. During the racking process, I managed to knock over the graduated cylinder with the hydrometer still inside.Mistake #3 The plastic guard ring around the cylinder saved it from breakage, but the hydrometer was not so lucky. On my first brew, I broke my first hydrometer. From what I understand, this will be the first of many such incidents in my time brewing.

So… people will say heating the mix will drive off alcohol and flavors. Brian and Derica from City Steading Brews explained they found the flavor change to imitate aging and isn’t a negative change at all. Further, the vapor temperature of ethanol (alcohol) is 173.1F. Yes, there will be some ethanol that, nonetheless, vaporizes and leaves the Mead while I’m heating it. I’ll choose to see that incredibly tiny, inconsequential, barely enough to change the ABV by a hundredth of point amount of alcohol as Odin’s share of each batch. Knowing the yeasties are dead and the Mead is safe for storage far outweighs any drawback to heat.

Backsweetening

Once pasteurization was complete, I backsweetened the mead with more homemade blueberry syrup and about 1 cup of white sugar. I wanted the blueberry flavor to be the star of the show and thought I had done a decent job of keeping it in the forefront. But, probably since this is my first batch, I found the blueberry flavor to be kind of lost in the honey and alcohol flavors. It also tastes pretty “young” which means it has some very upfront ethanol flavors (I think) that aren’t unpleasant… but kind of steal the spotlight. Once I had the sweetness level where I wanted it, I placed a freshly sanitized rubber cork and airlock on the carboy and will leave it to settle in and age a bit. I will probably bottle it in a few months. I don’t have a final SG because of Mistake #3. Baaahhh!

All gone

Well it didn’t last very long. I didn’t have wine bottles to bottle the Mead in so I had to leave in the carboy I pasteurized in. Knowing it had a ticking timer until oxidization, I put it in the garage fridge and made regular visits. And to be honest, it really was just THAT good. The next brews will be bottled appropriately and aged. Thanks for following along!

Be sure to check out my other brews.

Mistakes (Lessons learned)

- Mistake #1 – I pitched the yeast directly into the carboy. This means if the yeast was dead or bad, the whole batch would be wasted. Always use warm water or draw off some must to activate your yeast before adding to the main volume.

- Mistake #2 – I wanted to aim for about 15% ABV. I found out later that a starting ABV of 1.070 pretty much locks in the theortical maximum ABV at around 9.6%-ish. So, two days in, I added in the blueberry syrup mix.

-

Mistake #3 – I left the hydrometer inside the graduated cylinder which was sitting on the counter in the immediate work area.