Hulk Mead

I was sitting trying to think up some interesting new ideas to try with making Mead and I saw a picture in the Mead Facebook group of someone that added green food coloring and food glitter to a Mead they made. I have to admit, it looked really dang cool. But I’m one of those weirdos that doesn’t like to use a lot of “not food” in my food. So I set to thinking of a way I could do a natural green Mead. This is the craziness I came up with.

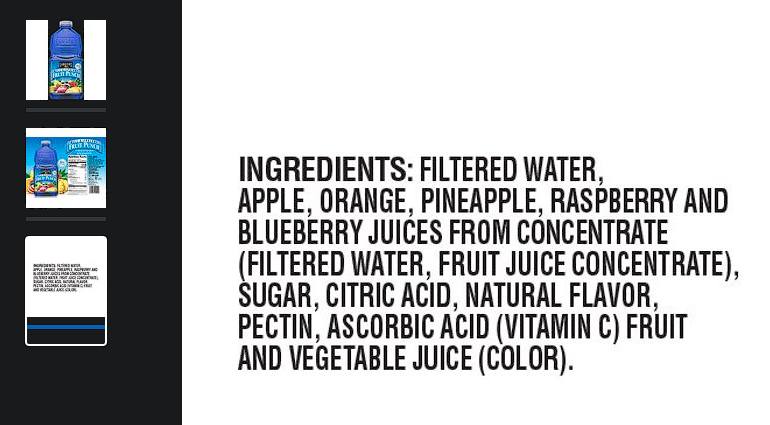

NOTE! I’ve been told the link for the Langers Blue Raspberry Fruit Punch in the ingredients doesn’t always link to the correct juice. Typical Walmart…………. Double check the ingredients and verify it matches this:

Section Index

Ingredients

- 45oz Langers Blue Raspberry Fruit Punch

- 2.5lbs Pure ‘N Simple Honey

- 1/2tsp FERMAID-O

- tea of 1 black tea bag in 4oz water

- 20 finely chopped raisins

- Lalvin D47 yeast

Preparation

After thoroughly washing and sanitizing all involved equipment, I started by pouring about 45oz of the Blue Raspberry Fruit Punch into a sauce pan and bringing it up to 160F for about 20 mins. This was done for two reasons: The first and most important I didn’t see any notes on pasteurization on the bottle so I wanted to be sure there were no foreign microbes present. And second, my wife and I might have gotten into the bottle as a mixer for an excellent huckleberry vodka called Blue Ice. I’m not getting any kickbacks from them, just wanted you all to know that this fruit punch and that vodka was quite tasty. Anyway, the important thing is this fruit punch is colored with fruit and vegetable juices and NOT DYES.

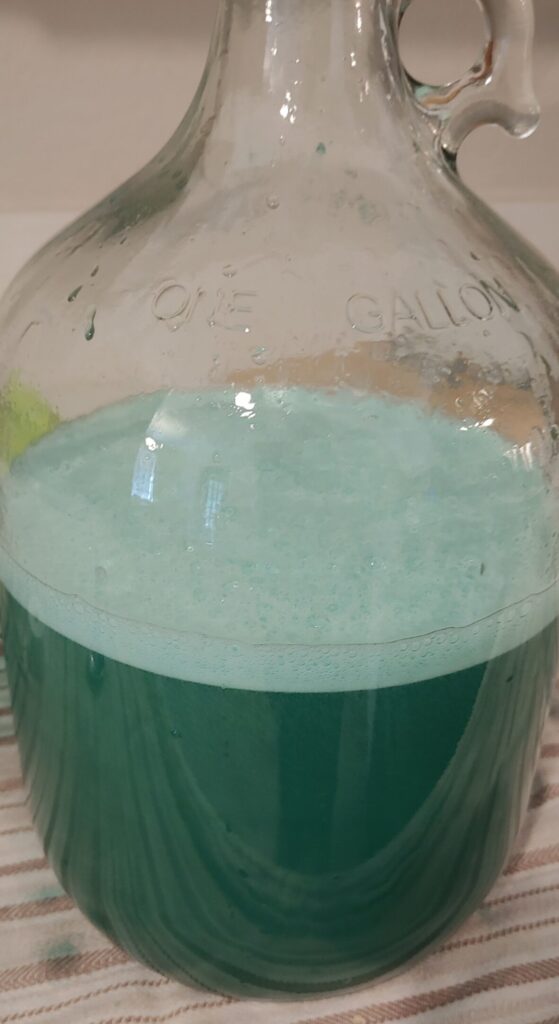

Once the punch had stayed at 160F for about 20 mins, I added the FERMAID-O directly to it (warm/hot stuff dissolves solids better/faster than cool stuff) along with the tea of 1 black tea bag. I put my funnel into the carboy and started adding honey. It’s a long process because my funnel isn’t very big and the honey moves slowly through it. Once I had 2.5lbs in the carboy, I poured the punch mixture into the carboy through the same funnel. The mixture had cooled to about 105F by this point, but is was still warm enough to melt the lingering honey in the funnel. Once all the punch was added, I screwed on my carboy sealing cap and “shook the bejesus” out of it, as Brian with City Steading Brews likes to say. This not only starts to mix the honey and punch together, but allows an opportunity to thoroughly oxygenate the Must. Oxygen is important at the beginning to help the yeastie beastie colony get a good foothold.

I chopped up the raisins and tossed them in and then added enough cold, filtered water to bring the contents up to 1 US gallon. I again capped the carboy and shook vigorously again until the honey, punch, and water were thoroughly mixed. I drew up a sample into my graduated cylinder using my turkey baster and measured the density with my hi-break-ometer (no, that joke doesn’t get old because they always break). The beginning density measured 1.106 Specific Gravity (SG), but the Must was still about 80F so the true measurement was probably just a couple thousandths above that. With everything used to draw and measure the sample having been sanitized, I added the portion back to the carboy.

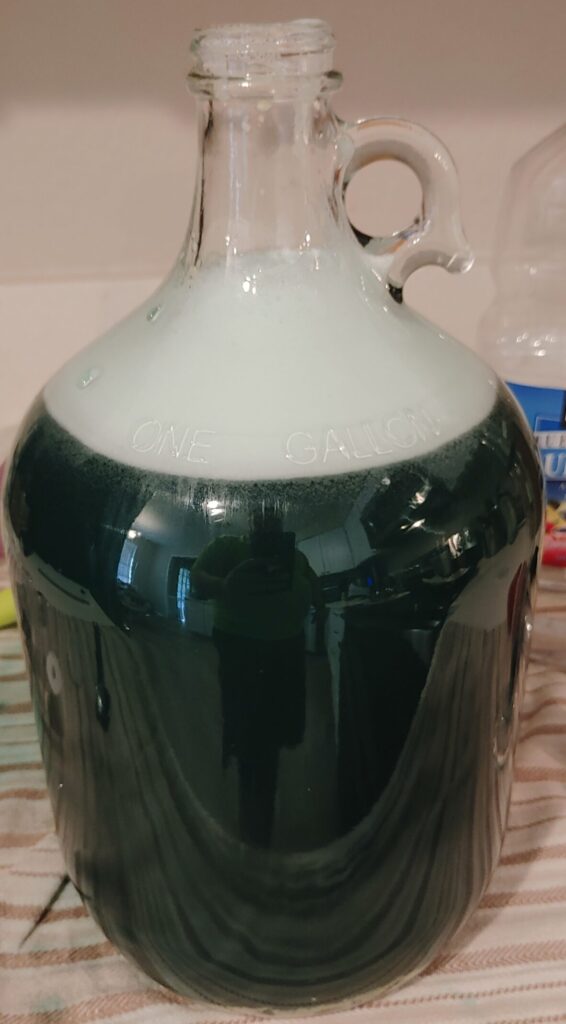

I pitched a full package of Lalvin D47 yeast for this one mostly because I didn’t feel like having an open package in the frig. There was a lot of persistent foam in the carboy, so I capped it again and shook it around some to wet and absorb the yeast. I put a bung in the carboy and added a 3-piece airlock filled to the line with some nasty cheap vodka since fruit flies are beginning to come out. The foam in the neck was so persistent, I was worried about having a puker so I decided to get a blowoff tube ready.

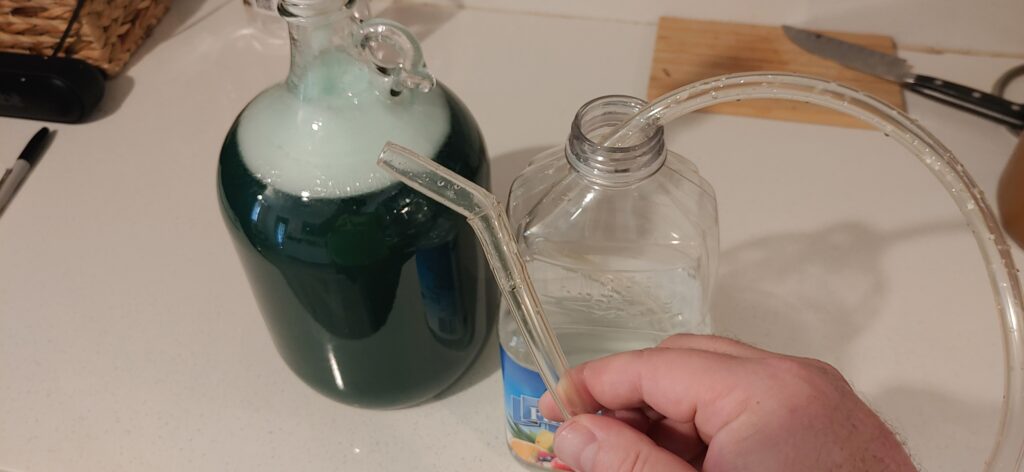

The Blowoff

I broke a S-type airlock as soon as it arrived from Amazon. This was a while ago, but I kept it thinking I could probably find something to use it for at some point. Lo and behold! I did. I cut off the part of the airlock that goes into the bung and got some extra tubing. The opposite end of the tip fit perfectly into the tubing. So I fed the tube into the bottle the punch came in, ran some water about halfway up the bottle, and sat it aside. I actually didn’t end up needing it, but it was a very cool side-note project.